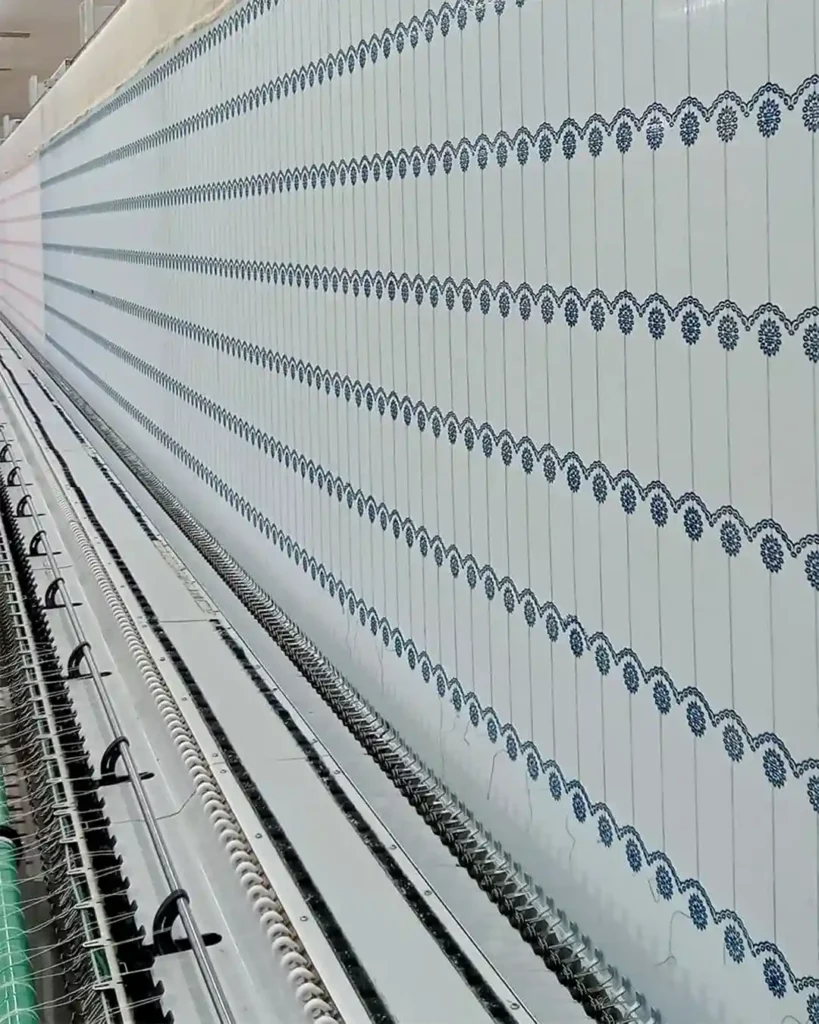

A reliable supplier of embroidery fabrics will be the deciding factor in the production workflow, making choosing the Right Embroidery Factory a critical business decision. The quality and continuity of your fabrics directly influence your product line, whether you run a fashion brand or an export unit. With so many manufacturers and exporters in the market, identifying what sets a strong embroidery partner apart from a mediocre one can be challenging but understanding these differences makes the selection process far more effective.

Start by Checking the Quality of the Product

The first thing quality should always be is your filter. A professional embroidery fabric supplier will always give you a consistent type of fabric that can hold stitches properly, that will not be puffed up, and that will keep its original shape after being embroidered. Check whether they offer samples, inquire about GSM ranges, and research their thread compatibility. Good suppliers also maintain clear quality control records. In case the supplier claims to be a wholesale embroidery fabric supplier, it means they are able to provide uniform quality even for large orders.

Consider Their Composition of Materials

The best suppliers provide not just one category but also a wide selection of fabrics. This includes cotton, lawn, chiffon, net, organza, jacquard, and other blends that are widely used for embroidery. If a supplier is also an embroidery fabric factory based in Pakistan, you will more likely find a greater variety, as many of the factories produce fabrics in-house. A comprehensive catalog is really beneficial to fashion brands that want to try out new collections without the hassle of changing suppliers all the time.

Check Customization and Design Support

In the case of many, there is the need for custom fabric runs in different colors or thread densities for certain designs, like these surface embroideries. The handling of such custom dyeing, special weaves, and seasonal design variations should be the responsibility of a good fabric exporter for embroidery. If you suspect that customization will be a major factor for your brand, it is better to check the supplier’s ability to perform in both the artistry and technology areas.

Evaluate Lead Times and Reliability

To be on time is the number one priority for export buyers and fashion houses. Consequently, it is essential to talk to your supplier first about the production time, delivery intervals, and the smallest order quantities. An honest supplier will keep you updated on any disruptions, will provide you with a good understanding of their capabilities, and will have no trouble maintaining the quality for repeat orders. Consistency is prioritized over speed; hence, you should try and find a supplier who has a history of timely delivery and that too at the same high-quality standards.

Compare Pricing, but Do Not Chase the Lowest Bid

Price is an important factor to consider, but on the other hand, an extremely low price quotation means, in most cases, poor quality or unreliable supply. Price a supplier whose price mirrors good fabric, strong production capacity, and reliable service. During the course of the partnership, placing value rather than cost alone will be the common approach with you.

Check Their Certifications and Compliance

If you will export your products, then it is a must that your supplier has the compliance with the basic standards. These might include environmental certifications, safe dyeing processes, and ethical manufacturing. Compliance is crucial, especially when it comes to selling garments in international markets.

Establish a Long-Term Partnership

After locating the perfect supplier of embroidery fabrics, your next step should be to build a strong relationship. Open lines of communication and share projections and bookings well in advance to facilitate smooth operations in both directions. Quality suppliers will always be there, support your expansion, and give you their services with top priority during peak seasons.

FAQs

1) How to select a fabric supplier?

Pay attention to their quality, range, reliability, pricing transparency, and capacity for managing custom orders. Before committing, ask for samples.

2) Which fabric is best for embroidery?

Cotton, lawn, organza, chiffon, net, and blended fabrics work well because they hold stitches firmly without puckering.

3) What are the questions I need to ask an embroidery fabric supplier?

Find out about minimum quantities for orders, delivery times, controllership of quality, options for custom work, and availability of samples.

4) Is it more advantageous to work with a factory rather than with a trader?

Factories can provide lower pricing and higher customization, while traders can supply a wider range coming from different mills. So, it kind of depends on your requirements.

5) Why do some embroidery fabrics cost more?

Higher thread density, premium yarns, complicated techniques, and custom dyeing all contribute to the increased costs.